EUV Optics

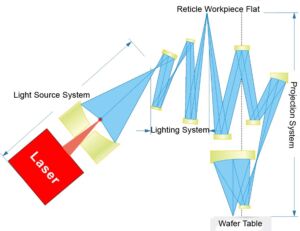

Extreme ultraviolet lithography (EUV) is a projection lithography technology with 13.5nm wavelength EUV as the light source. It is the mainstream technology to realize the line width of 28nm exposure node and below. In the light source system, high-energy laser is usually used to bombard the target. The target will be ionized and produce high-intensity plasma, and emit extreme ultraviolet light. In this working band, the transmittance of transmission material is low, so the reflective structure is needed for EUVL optical system including lighting system and projection system. The schematic diagram of the optical system is shown in the figure below:

In the figure above, the light from the light source system irradiates the mask with pattern evenly after passing through the lighting system, and carries the mask pattern information to reflect into the projection objective system. Finally, the mask pattern is imaged on the wafer surface coated with photoresist, and the whole mask is imaged and exposed by scanning.

The preparation of mirrors in extreme ultraviolet lithography is mainly divided into two steps: one is to grind and polish the substrate surface of mirrors to the required surface shape and surface roughness; the other is to coat multilayer optical films on polished mirrors to meet the requirements of reflection.

At present,Mloptic has the ability of ultra smooth surface mirror processing and thin film preparation. It can process coaxial and off-axis mirrors with an aperture of less than 400mm. The RMS value of surface shape is better than 5nm, and the surface roughness of components is better than 0.5nm.

The mirror image is as follows:

|

|

|---|