Optical Coating

MLOptic can apply most of the optical coating types and also some customized special coatings to all kinds of glass, IR crystal and metal substrates. According to customers special application and demand, we can use our expertise of coating design and performance analysis to help customers find the best coating solution.

Common types:

|

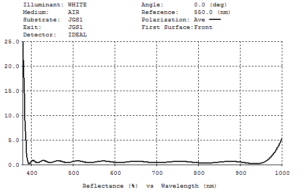

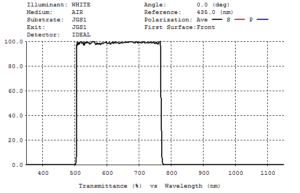

AR coating

|

|---|---|

|

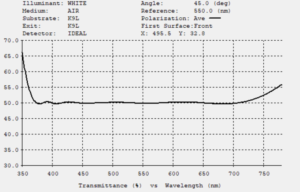

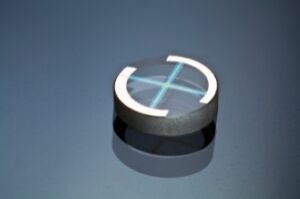

Beam splitter

|

|

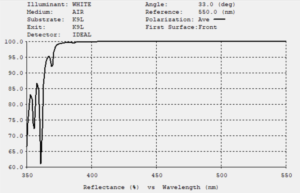

HR Coating

|

|

Filter

|

|

ITO coating

Electrode Coating |

|

Others

|

Coating Technology:

With both evaporation and sputtering coating chamber, we can flexibly use the appropriate material and process to achieve the specific need of the customer.

RF Ion Beam Source is the most powerful ion beam source, which make the micro-structure of the coating more compact, then guarantee the zero shift of the coating curve, especially in the case of narrow band pass filter.

Oil free vacuum system avoid the surface or coating contaminated by oil, then significantly improved the durability of the coating and lowers the absorption, especially in UV coating.

Equipped with Ф1900mm coating chamber, we can coat substrate with diameter up to Ф1600mm